Filtrona Porous Technologies

Polyurethane Foam Dressings for Wound Care

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Filtrona Porous Technologies is a world leader in the development and production of liquid and vapor handling products, engineered from bonded fiber, polyurethane foam, and porous plastic technologies. Our customized components result from a collaborative process designed for quality and reliability — every time.

Customized dressings for wound care

Used in medical and surgical devices, our customized products perform a wide variety of fluid-handling functions, including:

- Absorption

- Filtration

- Wicking

- Repellency

- Controlled release

Filtrona Porous Technologies’ collaborative development process creates high-quality, innovative solutions designed to meet our customers’ needs. We work with you to understand your needs and solve product challenges. Our engineers and dedicated R&D team reliably solve product challenges, meeting performance and specification requirements, on time and every time.

Advanced wound care solutions

All of Filtrona Porous Technologies’ products are manufactured from proprietary processes and a broad selection of material choices, both of which enable customized performance.

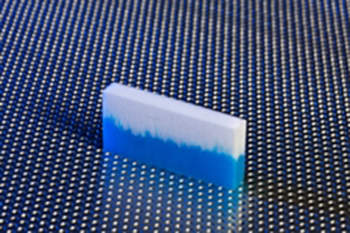

Filtrona Porous Technologies components are highly adaptable to meet precise fluid absorption or leak resistance challenges for medical and surgical devices. Primarily used in wound care applications, our hydrophilic polyurethane foams are manufactured from an industry-unique process and achieve super absorbency to rapidly wick exudate. The foam can also be custom formulated for a variety of wound care applications, including conventional and specialty dressings.

Key attributes of our polyurethane foams include:

- Customizable formulations

- Range of densities and porosities available

- Hydrophilic – highly absorptive

- Medical grade – ISO 10993 approved

- Catalyst-free and hypoallergenic – skin contact friendly

- Laminations available

- Roll stock and converting available

- Skived or poured to thickness

- Custom additive incorporation, including antimicrobials and pharmaceuticals

Other fluid-handling solutions

Filtrona Porous Technologies offers additional fluid management capabilities used beyond traditional wound care dressings. These technologies include bonded fiber and porous plastic.

Key attributes of bonded fiber include:

- Polyester, polyolefin, nylon, cellulosics, and other fiber materials

- Capillary structure

- Hydrophilic or hydrophobic

- Chemically and high temperature resistant

- Impregnation with, activated carbon, zeolites, cyclodextrin complexes, pigments, surfactants, reagents, or concentrates

- Customized 3-dimensional shapes; custom colors; roll stock and die-cutting

Key attributes of porous plastic include:

- HDPE, UHMWPE, and other materials

- Tortuous path structure

- Hydrophobic or hydrophilic

- Flexible or brittle

- Additives available, including self-sealing, color, and more

- Customized 3-dimensional shapes; excellent dimensional control

Contact Details

Email Address

Address

Colonial Heights,

VA 23875,

Other,

United States of America